Lonyan Eteng Eletronics Co.,Ltd Conductive adhesive tape,EMI Gasket,Thermal Pad |

Conductive Fabric

Introduce

The conductive fabric is fiber cloth (commonly used polyester fiber cloth) as substrate, the fabric is conductive after pre-processed with metal plating .it combines highly conductive metals with lightweight fabrics to meet a diverse range of EMI shielding requirements. Whether used as an architectural shielding product to shield complete rooms, or as the shielding material in EMI gaskets, tapes and shield laminates, ESD(electric static discharge) gamemts and packing materials,shielding tents and shielding rooms.Conductive fabrics provide a highly effective shielding system that is cost effective and easily applied. The lowest sufface resistivity could reach at 0.005ohms/sq.

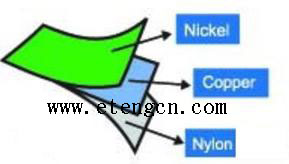

Structure

Specification

| Physical Properties Material Nylon/PET/Cu+Ni Thickness 0.12mm ±0.02mm Width 1450mm ±5mm Surface Resistivity <0.05 Ω/sq. Abrasion Test 500,000 cycles |

Shielding effectiveness dB: |

The above material is flexible and may be easily wrapped to form a compressible gasket.

It is also suitable for die cutting.

Classify:

As knitting:

Rip stop fabric

Plain weave fabric (polyester taffeta)

Non woven fabric

Standard is rip stop and plain weave fabric

As metalized:

golden plating

copper plating

siliver plating

aluminum plating

Nickel plating

Nickel +coppe plating

Standard one is sliver gray and aluminum fabric, aluminum fabric is low cost

.Application

Can be used to engage in electronic, electromagnetic and other high radiation work professional shielding work clothes, shielding room special shielding cloth; IT industry shield special cloth, the current popular touch screen gloves, anti radiation curtains and so on.